Systems Analysis

As specialists in electrical power distribution system design and protection, our electrical engineers are well qualified to assess your system and make appropriate recommendations. A well-designed power system is the backbone of all industrial and commercial facilities. A power system study will provide you with the information necessary to upgrade and maintain your power delivery infrastructure. The results focus on reducing operating costs, improving efficiency, increasing reliability, and improving system safety and maintainability. Our engineers have the expertise to provide the following services:

Single Line Diagram Generation/Revision

NFPA 70E requires updated Single Line Diagrams as a means to insure safety for plant operators and maintenance personnel. Maintaining accurate drawings is often not a top priority especially at older, document-challenged facilities or those that have experience significant growth or renovation. Our electrical engineers and designers will survey your facility and construct a set of comprehensive and up-to-date power system single line diagrams.

Updated single line diagrams will:

Updated single line diagrams will:

- Allow for greater ease of on-site electrical system trouble shooting

- Reduce potential mismatches when adding-on to an existing facility

- Provide the most up-to-date information for performing accurate power system studies

Short Circuit Study

The National Electrical Code requires that all short circuit interrupting devices have capabilities beyond the duties imposed by the power system. A short circuit study can provide information to help determine if the interrupting capacities of your power system’s components provide adequate protection.

Our engineers will calculate the short circuit fault current levels at different locations in the power system. We will compare these calculated fault currents to your equipment short circuit interrupt/withstand ratings in order to determine if you have a problem. This data may also be utilized as the basis for a protective device coordination study or an arc flash hazard analysis.

- Identify underrated equipment before extensive system damage can occur

- Increase facility reliability, equipment protection and personnel safety

- Aid in future expansion plans

Protective Device Coordination Study

You can help ensure ongoing, reliable operation during a fault by periodically evaluating the protective devices in your power system. The goal of a protective device coordination study is to assure the system is capable of clearing a fault in the minimum amount of time possible, while minimizing the impact to the power system. A protective device coordination study may also include recommendations for revisions of the types of protective devices for improved protection.

Our electrical engineers will determine the proper settings for your protective devices (circuit breakers and relays) and ampacities of power fuses in the distribution system. These settings and ampacities will be determined by plotting the time-current curves of the devices and applying NEC, IEEE, ANSI and UL standards.

A protective device coordination study will:

A protective device coordination study will:

- Increase equipment protection

- Ensure protective device coordination by setting the protective devices to trip in sequence

- Increase facility reliability by limiting the effects of a disturbance

Arc Flash Hazard Study

Our comprehensive arc flash hazard analysis is designed to help ensure employee safety against dangers associated with the release of energy caused by an electrical arc. Key elements of an arc-flash hazard analysis include determining the required level of personal protective equipment (PPE) and communicating PPE and safe approach distances through an effective warning label system.

An arc flash hazard study will:

An arc flash hazard study will:

- Increase the awareness of arc flash hazards

- Increase facility reliability, equipment protection, and personnel safety

- Ensure compliance with OSHA, NESC, NFPA, and NEC requirements

Load Flow Study

A load flow study is essential in evaluating circuit loading, bus voltage profile, real and reactive power flows, and power system losses. A load flow study will model how your power system will operate under normal and emergency loading conditions.

Our electrical engineers can model multiple operating scenarios to ensure that your system is adequately designed to satisfy current and future operating requirements.

- Aid in future planning and present day operation

- Determine the proper transformer tap settings

- Identify under-utilized equipment which will allow for future load growth

- Identify overloaded equipment

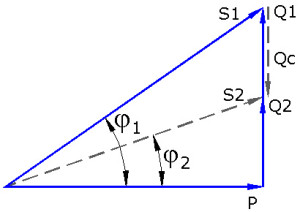

Power Factor Study

Wasted energy capacity, also known as poor power factor, is often overlooked. It can result in higher energy costs, safety problems and, in some cases, additional financial charges. Most electrical rate tariffs contain provisions that include a minimum power factor requirement. Customers who fall short of the minimum power factor level are assessed a power factor charge. Other consequences of a low power factor include decreased system capacity and increased system losses.

A power factor study calculates the reactive load compensation required to achieve and sustain a specific power factor. Our electrical engineers will select the size and location of capacitors to improve power system efficiency and eliminate penalty charges.

- Reduce your electric bill and eliminate utility penalties

- Ensure proper sizing and placement of capacitors

- Improve bus voltage profile

- Verify that there will be no abnormal interaction between harmonic sources and the capacitors

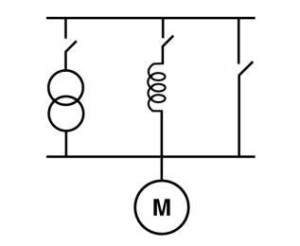

Motor Starting Study

A motor starting study will determine your system’s ability to start large motors or other impact loads. Such a study is critical before installing a large motor to make certain that your system can start the motor successfully without causing detrimental operating effects due to voltage and frequency fluctuations.

Our electrical engineers can model and simulate the motors starting on your distribution system. We will calculate flicker and voltage drop due to motor inrush current. We will also determine the best method to start the motor with minimal impact to the rest of the distribution system.

- Reduce voltage flicker or voltage drop problems in the facility

- Increase facility reliability

Harmonic Study

Harmonic analysis has become more important due to the application of AC & DC adjustable speed drives, converters and other equipment that produce harmonic distortions. These non-linear loads generate harmonic currents that interact with system impedances. These interactions may result in equipment malfunction and/or damage to the power system. A harmonic study analyzes the system and recommends corrective measures, which include the design of filters or traps to absorb harmonic currents generated by non-linear loads.

Our electrical engineers will identify harmonics generated by non-linear equipment. The study will determine if your facility exceeds the IEEE 519 limits. We will also determine harmonic mitigation techniques to reduce the harmonics.

- Identify the source of harmonics

- Evaluate the impact of non-linear loads on facility distribution systems

- Evaluate compliance with IEEE 519

- Verify proper size and placement of capacitors when harmonic sources are present

- Verify proper size, configuration and placement of filters, if necessary

Reliability and Availability Study

Equipment failure is a fact of life; it will happen. A complete or partial shutdown of a power system can greatly affect the production profits of a plant. Our electrical engineers are well aware of the factors that affect power system reliability and the associated cost to provide that reliability. Using industry-accepted reliability figures and methods outlined in standards such as IEEE 493, system failure rates can be calculated. These system failure rates can be converted to risk cost to justify reliability improvements to the power system.

The rate of return on investment for various designs can be compared with the system reliability alternatives to provide a basis for more informed decisions.

A reliability and availability study will:

A reliability and availability study will:

- Allow analysis of the investment requirements of various design alternatives

- Provide justification of the optimum system design

- Identify preventative maintenance investment opportunities